Fontana

Kaiser Steel

13340 San Bernardino Ave. (@ California Steel Wy.), Fontana

La acería Fontana de Henry Kaiser, inaugurada en 1942, fue la primera de su tipo en la Costa Oeste. Prosperó durante la Segunda Guerra Mundial y a lo largo de la Guerra Fría. La planta suministró materiales para alimentar el auge del gasto de consumo posterior a la guerra, al mismo tiempo que sentó las bases para el nuevo imperio logístico de la región.

Kaiser se hizo un nombre construyendo carreteras, presas y barcos de carga, infraestructuras clave para el crecimiento de California. Desafió a los grandes aceros del este al tomar préstamos federales para la guerra y al integrar verticalmente su producción desde materias primas hasta placas acabadas, vigas, tuberías y millones de proyectiles de artillería pesadas. Con los hornos rugiendo y los hornos de fundición a cielo abierto en llamas, los negocios prosperaron en Kaiser. Su caída se produjo con la competencia global de la década de 1970. En su apogeo, Kaiser empleaba a 9,000 personas. Estos empleos se perdieron. El pesadillo tóxico clasificado como Superfund permaneció. Décadas después, una pista de carreras y millones de pies cuadrados de centros de distribución ocupan la propiedad de Kaiser, con un plan maestro para desarrollar otro sitio de mega-logística. Los desarrollos de viviendas se encuentran al lado de millas de depósitos de chatarra, plantas de reciclaje y empresas de transporte, todos conmemorando el pasado militar e industrial de Fontana.

Desde los Archivos

por A People’s History of the I.E. [Una Historia Popular del I.E.]

Haz clic en las imágenes de abajo para descubrir la historia.

“¡De cerdos a hierro de cerdo!”

—Eslogan de la acería Kaiser, 1943

Fontana en el siglo XX fue de las primeras agronegocios promovida a través de imágenes románticas. En las décadas de 1910 y 1920, en el pueblo se plantaron 95,000 árboles de cítricos y terrenos dedicados a pollos, conejos y la granja de cerdos más grande del mundo. Su apariencia pastoral podía ser engañosa.

“Los veteranos recuerdan los olores competidores del excremento y la basura,” según Ernie Garcia. Los Ángeles enviaba su basura aquí para alimentar a los cerdos, cuyo estiércol luego fertilizaba los huertos.

La contratación estacional en Fontana durante la cosecha incluía trabajadores inmigrantes de muchas naciones. El Sherman Institute, la escuela de internado para nativos americanos fuera de la reserva en Riverside, también enviaba a cientos de jóvenes indígenas a trabajar en las granjas de Fontana.

Foto: Granja de cerdos, Fontana, ca. 1935, cortesía de la Biblioteca Pública de Los Ángeles, Colección de Fotos de la Cámara de Comercio Earl Powell

“¡Fontana Steel construirá un mundo nuevo!”

Fontana Herald-News, 7 de enero de 1940

Los lotes de 2.5 acres en Fontana eran lo suficientemente grandes para un jardín y un gallinero. Prometían a los colonos autosuficiencia y un alivio de las chimeneas de la vida industrial urbana en el Este. Hasta al menos 1942.

Kaiser trató de diferenciar su fábrica de otras ciudades siderúrgicas. Promovió la estética y el paisajismo, sugiriendo que el molino estaba en armonía con los huertos de cítricos. Minnie Luksich, cultivadora de cítricos, fue una de las que no se dejó convencer. Ella había estado en contra de ubicar la planta en Fontana, temiendo las emisiones. Más tarde dijo: 'No teníamos dinero para hacer nada al respecto.' Eventualmente consiguió un trabajo allí.

Foto: Horno de alto horno, Kaiser Steel, 1944, Instituto Americano de Hierro y Acero, cortesía de la Biblioteca y Museo Hagley

En 1950, un agente inmobiliario de Los Ángeles puso a la venta más de 5,000 acres de huertos y viñedos que rodeaban la planta de Kaiser para el “desarrollo privado de la industria de defensa”. La expansión militar de la Guerra Fría en las bases aéreas cercanas continuó el mercado del acero. Sin embargo, el humo en la foto de prensa llama la atención sobre los problemas medioambientales que afrontó Kaiser desde el principio. La altura de las chimeneas tenía como objetivo elevar y alejar los humos. No funcionó.

Algunos locales veían las altas chimeneas como una fuente de contaminación para el valle, destruyendo sus cultivos y forma de vida. Otros lo expresaron de manera más directa, como dijo un ex trabajador del acero más tarde: ‘Demonios, ese humo era nuestra prosperidad.’

Foto: Vista aérea de Fontana con Kaiser Steel en el centro, 1951, © Cámara de Comercio de EE. UU., cortesía del Museo y Biblioteca Hagley

A partir de 1948, el molino Kaiser se alimentó del mineral de hierro extraído de Eagle Mountain, adyacente al actual Parque Nacional Joshua Tree en el Desierto de Mojave. Kaiser creó una ciudad completamente nueva para trabajar allí, tomando agua del parque para mantener verdes los jardines de los residentes y abierta la piscina comunitaria. Sus equipos construyeron 52 millas de rieles para sus vagones privados, que transportaban mineral desde la mina hasta la línea de Southern Pacific en Ferrum (cerca del Mar de Salton) hasta Fontana. También sirvió como destino turístico.

Las casas de estilo rancho y los bungalows en Eagle Mountain aún permanecen, como un pueblo fantasma. Los defensores del parque resistieron los planes para que el terreno se utilizará como un vertedero de desechos. Los propietarios actuales no han revelado su intención para la propiedad.

Aquí está la parte de la excursión en el ferrocarril de Eagle Mountain de Kaiser, desde Ferrum hasta la mina, 1950. © Richard Steinheimer, cortesía de la Biblioteca DeGolyer, Universidad Metodista del Sur

Tanto la minería de hierro como la fabricación de acero son procesos intensivos en agua y energía, utilizando combustibles fósiles para alcanzar temperaturas suficientemente altas para fundir el hierro y el carbón en acero.

Kaiser Steel nunca contribuyó a la base impositiva de la ciudad. Permaneció como una entidad no incorporada con sus propios sistemas de agua y energía. Sus emisiones tóxicas y aguas residuales no se mantuvieron tan contenidas. Más bien, la fábrica liberabero enormes cantidades de arsénico, cromo, plomo y otros contaminantes peligrosos del aire en las comunidades cercanas.

‘Piensa en la seguridad’ reza el cartel en la pared junto al enorme horno, al otro lado del puente del Lilliputian a la derecha, ca. 1958. Colección Will Connell, cortesía del Museo de Fotografía de California, Universidad de California, Riverside

Fontana se convirtió en el hogar de una mezcla incómoda de personas a medida que miles llegaban y luchaban por encontrar vivienda. Vivían en dormitorios temporales, remolques dentro y fuera de los terrenos de Kaiser, y en sus automóviles. Las restricciones raciales confinaban a las familias negras al norte de Foothill Blvd. Los latinos se concentraban al sur de la I-10. Los blancos de clase trabajadora se encontraban en el centro de la ciudad. Desde 1943 hasta 1964, braceros de México ocuparon los trabajos agrícolas que habían dejado las personas que fueron enviadas a la guerra y a mejores posiciones sindicales.

La línea marcada de color y la historia de la actividad del Klan en la zona llevaron a la violencia en diciembre de 1945, cuando O’Day Short se mudó con su familia a Fontana para comenzar un nuevo trabajo en Kaiser Steel, estableciéndose en un vecindario blanco. Fueron visitados por vigilantes, probablemente miembros del Klan, y la Cámara de Comercio de Fontana ofreció comprarlos. Unas noches después, un incendio consumió la casa, matando a la familia de cuatro. Aunque los testigos afirmaron que fue un incendio intencional y un investigador de la NAACP también lo consideró así, el gran jurado se negó a permitir que los testigos subieran al estrado y el fiscal del distrito calificó el incendio como un accidente.

Terror de Vigilantes en Fontana, 1946, cortesía de la Biblioteca Bancroft

“En aquellos tiempos, generalmente le daban a nuestra clase de gente trabajos sucios y desagradables. Y tenías que soportarlo. Pero lo único que tiene es que prevalecieron los sindicatos, la seguridad y la antigüedad sindical.”

—Dennis Green

En las décadas de 1940 y 1950, a medida que crecían los empleos industriales, los trabajadores negros encontraron nuevas oportunidades, pero permanecieron confinados a los trabajos más peligrosos, calurosos y tóxicos. Muchos hombres de San Bernardino trabajaron para Kaiser Steel, al igual que tres generaciones de la familia Greene, comenzando con Ernest Green. Él trajo su experiencia de la industria del acero en Pittsburgh a su nueva vida en California. Hasta que se implementaron los mandatos legales en la década de 1960, la colocación laboral para los negros seguía restringida a los peores trabajos.

Herbert Greene cuando se jubiló de Kaiser Steel en 1978 después de 45 años en la industria, cortesía de Dennis Green

“Kaiser Steel necesita una revisión en sus políticas de contratación… El desempleo es alto y pocos negros están siendo contratados… Los pocos que son contratados son puestos como obreros a pesar de las habilidades que puedan tener, y se les asigna a los trabajos menos deseables y más sucios – en la fundición, el alto horno o el horno de coque.”

—California Eagle, 1959

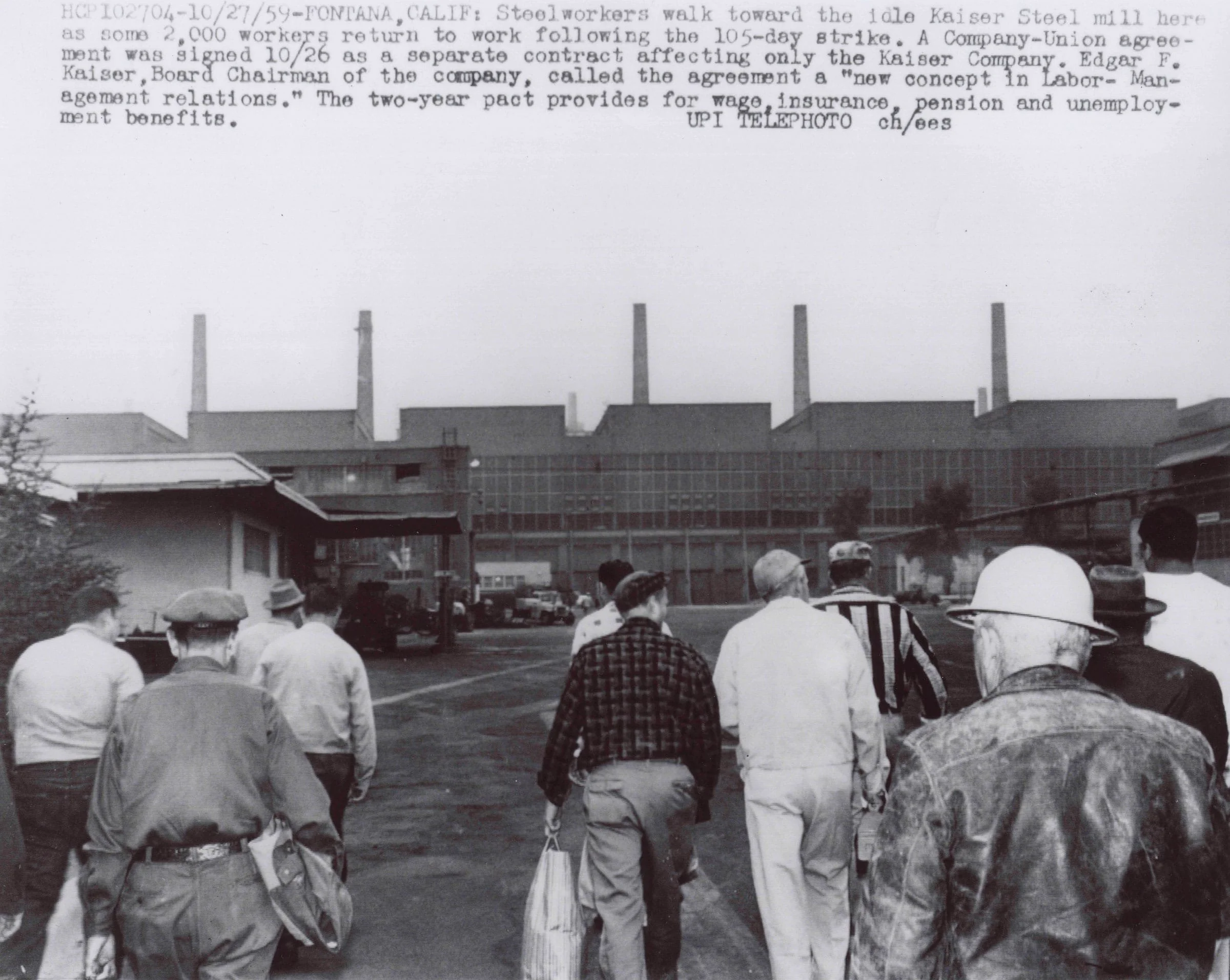

Kaiser se veía a sí mismo como un industrial benevolente, reconociendo que la atención médica y los bonos eran una forma de mantener la lealtad de los trabajadores. Pero los despidos frecuentes también significaban que estos empleos no siempre conducían a la estabilidad económica. La huelga de 105 días de los trabajadores del acero en 1959 tuvo estos problemas en su núcleo.

Algunos, como Raymond Robinson, Director de Asuntos Públicos de Kaiser, al ser entrevistado en 1976, sintieron que esto fue el comienzo del fin.

“Como resultado de esa huelga, los japoneses obtuvieron una posición fuerte en nuestro mercado de acero. Antes de ese momento, solo alrededor del dos por ciento del acero consumido en los siete estados del oeste... provenía del extranjero. Durante ese largo período en el que nuestros clientes no pudieron comprar acero, empezaron a comprarlo a los japoneses. Ahí fue donde comenzó.”

Los trabajadores del acero de Fontana regresan al trabajo, fotografía de UPI, 27 de octubre de 1959, colección privada

Kaiser Steel se declaró en bancarrota en 1983, vendió su maquinaria a una empresa china y comenzó a vender lentamente sus propiedades. Los mapas aéreos de Fontana hoy en día muestran cómo los usos industriales y de almacenes han reemplazado a la manufactura de acero, con una pérdida correspondiente de empleos sindicales con beneficios.

Las autopistas y ferrocarriles que facilitaron la distribución para la industria del acero ahora aceleran el movimiento de todo tipo de mercancías hacia y desde los almacenes. Los centros de distribución se agrupan a lo largo de las intersecciones de las autopistas 10, 15 y 60.

Al sur de la autopista 10, la densidad de almacenes, patios de camiones y áreas de descanso para camiones es especialmente alta. La Coalición de Ciudadanos Preocupados del Sur de Fontana es uno de los grupos comunitarios que se han opuesto a la construcción de almacenes junto a escuelas, al paso de camiones ruidosos por sus vecindarios y a la mala calidad del aire y de las carreteras. Después de que el Fiscal General de California presentara una demanda contra la ciudad, se estableció un fondo de beneficios comunitarios para "mitigar el impacto ambiental". Sin embargo, esto no detiene la nueva construcción.

Vista aérea de los almacenes agrupados en la intersección de las autopistas I-10 e I-15, incluyendo la pista de carrera de NASCAR que ocupó una parte de la antigua propiedad de Kaiser Steel, cortesía de ESRI Aerial Basemap.

Los camiones y almacenes han alterado el estado del trabajo y el paisaje de Fontana. Maninder Singh es un conductor de camiones de Punjab que vive en el vecindario. Él es uno de los miembros de su familia que comenzaron a llegar a Fontana a fines de la década de 1980, uniéndose a las decenas de miles que, junto con conductores mexicanos y centroamericanos, constituyen aproximadamente la mitad de todos los camioneros en California. Singh explica,

“Al principio, cuando los almacenes de Amazon llegaron por primera vez [a Fontana], no había restricciones sobre a dónde podían ir los camiones. Ni siquiera podías salir de tu entrada. Y justo cuando salías de la comunidad, había una maldita fila de camiones para ir a cualquier parte.”

Singh lo atribuye a una falta de responsabilidad municipal, afirmando que la ciudad aprueba los cambios de zonificación, toma propiedades y luego las vende a desarrolladores de almacenes. “Estas grandes empresas,” dice, “están comprando todo el terreno en Fontana.”

Uno de los numerosos patios de camiones en Fontana, 2024, foto de Tamara Cedré, cortesía de la artista

Sueños de Acero | Fontana

por Tamara Cedré

Precipitadores electrostáticos en Kaiser Steel, Archivo de American Heritage Publishing, 1959

Reproducción de negativo, fotografía en gelatina de plata

Colección privada

Huelga de trabajadores del acero en la planta de Kaiser Steel, Associated Press, 1959

Reproducción, impresión de pigmento de archivo

Colección privada

Fotocopia de Stacked Steel Slabs (Skullcracker Series) de Richard Serra, 1969, construida en Kaiser Steel, Fontana, en Maurice Tuchman, A Report on the Art & Technology Program of the Los Angeles County Museum of Art, 1967-71, 1971

Reproducción sobre dibond

Colección privada

Montaje de estructura de acero en Kaiser Steel, Frashers Fotos, 1952

Reproducción, impresión de pigmento de archivo

Colección privada

Tamara Cedré

Kaiser Steel Mill con vista al noroeste, 2024

Impresión de pigmento de archivo

Cortesía de la artista

Tamara Cedré

Catálogo general de Kaiser Steel, 2024

Impresión de pigmento de archivo

Cortesía de la artista

Pat Le Roy (secretaria, 19 años), sentada sobre el césped frente al edificio de administración de Kaiser Steel Mill, Fontana, 1952

Reproducción, impresión de pigmento de archivo

Biblioteca Digital de USC, Colección de Fotografías del Los Angeles Examiner

Mina Eagle Mountain—área residencial, mina y planta de beneficio al fondo, c. 1948

Fotografía en gelatina de plata

Sociedad Histórica de Fontana

Mojave Desert Ore Dravo, 1965

Anuncio publicitario

Colección privada

Tamara Cedré

Pueblo de la empresa Eagle Mountain, 2024

Impresión de pigmento de archivo

Cortesía de la artista

Tamara Cedré

Almacenes en Almond Avenue, Fontana, 2024

Impresión de pigmento de archivo

Cortesía de la artista

Motel Travelodge de Fontana, 1959

Folleto publicitario

Colección privada

Tamara Cedré

Registro de viaje de Fontana, 2024

Impresión de pigmento de archivo

Cortesía de la artista

Producciones Kaiser Steel, 2024

por Tamara Cedré

Montaje de metraje cinematográfico vintage.

Cortesía del artista.

Recursos

-

CCAEJ – Centro de Acción Comunitaria y Justicia Ambiental es una organización comunitaria que lucha por la justicia ambiental y la equidad en Bloomington y en todo el I.E.

El Inland Empire Labor Institute se asocia con organizaciones económicas, sociales y ambientales para priorizar las necesidades de los trabajadores en las comunidades y las familias.

PC4EJ – Colectivo Popular para la Justicia Ambiental lucha por la justicia ambiental y desafía las raíces culturales y sistémicas de la supremacía blanca.

La Coalición de Ciudadanos Preocupados de South Fontana está fundada por residentes locales que trabajan para garantizar que su comunidad tenga los recursos que necesita. @southfontana

-

City of Quartz de Mike Davis documenta la historia de Fontana en el capítulo “Junkyard of Dreams”

Climas de desigualdad, “Kaiser Steel y la lenta violencia de la cadena de suministro”.

Plug In I.E. y I.E. Labor Center, “State of Work: Transportation, Distribution and Logistics Report” (febrero de 2024) incluye datos y entrevistas con residentes del I.E., incluido Fontana.

-

La Sociedad Histórica de Fontana administra los archivos relacionados con la zona, incluido Kaiser Steel, supervisa dos sitios históricos (uno que era la casa de un capataz en el rancho de A. B. Miller, que ahora sirve como museo) y tiene una sala de historia en el Centro de Tecnología Lewis de la Biblioteca Pública de Fontana.

El Museo de Fotografía de California UCR ARTS conserva los archivos de Will Connell (más de 15.000 negativos e impresiones), quien fotografió a Kaiser Steel en Fontana para la empresa.